Utility poles are a crucial part of our infrastructure, supporting power lines, telecommunications networks, and streetlights. Understanding the cost of utility poles is essential for utility companies, contractors, and even homeowners who may need them for specific projects. This article will provide an in-depth exploration of the factors affecting the cost of utility poles, their types, installation processes, and maintenance requirements.

From the raw materials used to construct utility poles to the installation techniques and maintenance practices, this guide will cover everything you need to know about the cost of utility poles. Whether you're planning a construction project or simply curious about the economics behind utility infrastructure, this article will answer all your questions.

By the end of this guide, you'll have a clear understanding of the factors that influence the cost of utility poles and how to make informed decisions when purchasing or installing them. Let's dive in!

Read also:Unveiling The Secrets Of Night At The Museum Keys

Table of Contents

- Introduction

- Types of Utility Poles

- Factors Affecting the Cost of Utility Poles

- Average Cost Breakdown

- Installation Process

- Maintenance Costs

- Environmental Impact

- Regulations and Standards

- Cost Comparison Between Materials

- Future Trends in Utility Pole Costs

- Conclusion

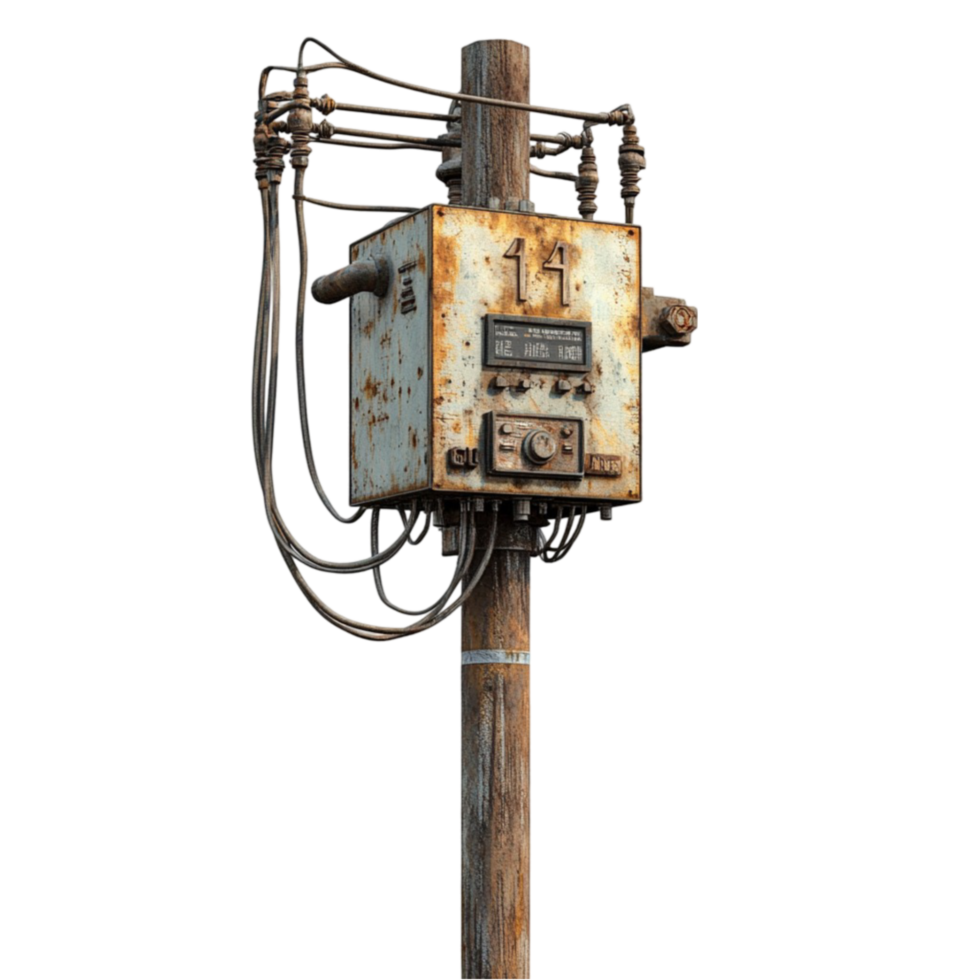

Types of Utility Poles

Utility poles come in various materials and designs, each with its own cost implications. The most common types of utility poles include:

Wooden Utility Poles

Wooden utility poles are the traditional choice and remain popular due to their durability and cost-effectiveness. Made from species such as southern yellow pine, Douglas fir, and western red cedar, these poles are treated with preservatives to enhance their lifespan.

- Cost: $150 to $500 per pole

- Advantages: Natural material, easy to install, and widely available

- Disadvantages: Susceptible to rot, pests, and fire

Steel Utility Poles

Steel utility poles are gaining popularity due to their strength and resistance to environmental factors. These poles are ideal for areas prone to severe weather conditions.

- Cost: $500 to $1,500 per pole

- Advantages: High strength, long lifespan, and recyclable

- Disadvantages: Higher initial cost and heavier weight

Concrete Utility Poles

Concrete utility poles are known for their durability and resistance to fire and pests. They are often used in urban areas where aesthetics and safety are priorities.

- Cost: $700 to $2,000 per pole

- Advantages: Fire-resistant, low maintenance, and aesthetically pleasing

- Disadvantages: Heavy and difficult to transport

Factors Affecting the Cost of Utility Poles

The cost of utility poles is influenced by several factors, including:

Material

The type of material used significantly impacts the cost. For example, wooden poles are generally cheaper than steel or concrete poles.

Read also:Unveiling The Secrets Of Two And A Half Men Casting A Comprehensive Guide

Height and Diameter

Taller and thicker poles require more material and labor, increasing their cost. Utility poles typically range from 20 to 120 feet in height.

Location

The cost of utility poles can vary based on geographical location. Transportation costs and local regulations also play a role.

Treatment and Coating

Treated poles, especially wooden ones, have a higher cost due to the preservatives and coatings applied to enhance their durability.

Average Cost Breakdown

Below is a breakdown of the average cost of utility poles based on material and size:

- Wooden Poles: $150 to $500

- Steel Poles: $500 to $1,500

- Concrete Poles: $700 to $2,000

For larger projects, bulk purchasing can reduce the per-unit cost. Additionally, custom designs and specialized treatments may increase the cost.

Installation Process

The installation of utility poles involves several steps, each contributing to the overall cost:

Site Preparation

Preparing the site for installation includes clearing the area, marking the location, and ensuring proper access for equipment.

Digging and Placement

Digging holes for the poles and ensuring proper alignment are critical steps in the installation process. The depth and width of the holes depend on the pole's size and soil conditions.

Securing and Anchoring

Once the poles are placed, they must be secured and anchored to ensure stability. This step is crucial for preventing damage during storms or high winds.

Maintenance Costs

Maintaining utility poles is essential to extend their lifespan and ensure safety. Regular inspections, repairs, and replacements contribute to the overall cost:

Inspection

Regular inspections help identify potential issues before they become major problems. Inspections may include visual checks, electrical testing, and structural evaluations.

Repairs

Repairs may involve replacing damaged sections, treating decayed wood, or reinforcing the pole's foundation.

Replacement

In some cases, replacing the entire pole may be necessary. This is particularly true for older poles that have reached the end of their useful life.

Environmental Impact

The environmental impact of utility poles varies depending on the material used. Wooden poles, for example, are biodegradable but may require chemical treatments that can harm the environment. Steel and concrete poles have a lower environmental impact but consume more energy during production.

Sustainability Initiatives

Many companies are adopting sustainable practices, such as using recycled materials and developing eco-friendly treatments for wooden poles.

Regulations and Standards

Utility poles must comply with various regulations and standards to ensure safety and reliability. These regulations cover aspects such as pole design, installation, and maintenance.

ANSI Standards

The American National Standards Institute (ANSI) provides guidelines for the design and installation of utility poles. Compliance with these standards ensures that poles meet safety and performance requirements.

Local Regulations

Local governments may impose additional regulations, especially in urban areas where aesthetics and safety are priorities.

Cost Comparison Between Materials

Comparing the cost of different materials can help in making informed decisions:

- Wooden Poles: Lower upfront cost but higher maintenance requirements

- Steel Poles: Higher initial cost but lower maintenance needs

- Concrete Poles: High initial cost but excellent durability and low maintenance

While wooden poles may seem more affordable initially, their long-term maintenance costs can outweigh the savings. Steel and concrete poles, on the other hand, offer better value over time due to their durability and low maintenance requirements.

Future Trends in Utility Pole Costs

As technology advances, new materials and construction methods are emerging, which may impact the cost of utility poles. Innovations such as composite poles and smart poles are gaining traction:

Composite Poles

Composite poles, made from fiberglass and other advanced materials, offer excellent durability and resistance to environmental factors. Although their initial cost is higher, their long-term benefits make them an attractive option.

Smart Poles

Smart poles integrate technology such as sensors and communication devices, enabling real-time monitoring and data collection. These poles are becoming essential for smart cities and advanced infrastructure projects.

Conclusion

Understanding the cost of utility poles involves considering various factors, including material, size, location, and installation costs. Wooden poles remain a popular choice due to their affordability, while steel and concrete poles offer superior durability and longevity. Regular maintenance and adherence to regulations ensure the safety and reliability of utility poles.

We encourage you to share this article with others who may find it useful. For more information on utility infrastructure, explore our other articles or leave a comment below with your questions or feedback. Together, we can build a safer and more sustainable future!

For further reading, consult the following sources: